BUSINESS

BUSINESS

Engineering

Theoretical knowledge and practical experience are harmonized in ISSAC E&C to provide time and cost efficiency for ordinary activities, and also to solve any complicate and critical problems facing on challenging circumstances.

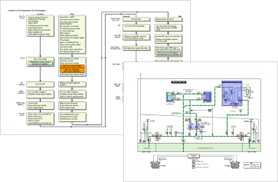

Basic Design

ISSAC E&C provides Basic Design for small and medium scale offshore & onshore development projects. Basic Design typically includes design premises, design philosophies, process flow diagrams, process descriptions, material balances, equipment lists, general designs and layouts, general specifications, main equipment data sheet specifications of long lead items, preliminary cost estimates, HAZOP/HAZID studies and risk analyses.

- Conceptual process studies (material balances, process flow sheets,…) and preliminary plot plan

- Preliminary piping and instrument diagrams

- Definition and sizing of main equipment resulting in process specifications

- Specification of effluents

- Definition of control and safety devices

- Thermal rating of heat exchangers

- Preparation of tender packages for the main equipment

- Development of process and utility piping and instrument diagrams released for detail engineering

- Development of detailed plot plans and hazardous areas

- Elaboration of the main piping, instrument, electrical and civil works layouts

Maintenance and Inspection Engineering (MIE)

Maintenance and Inspection Engineering (MIE) is an integral part of a technology management system, aimed to identify methods for developing and selecting maintenance and inspection strategies and design alternatives, based on operational, economic, safety and environmental criteria.

ISSAC E&C applies systematic approaches for establishing a maintenance and inspection program, which will efficiently and effectively allow the achievement of the required safety and availability levels of equipment and structures, intended to result in improved overall safety, availability and economy of operation.

The main objective is to provide a comprehensive and structured set of knowledge, addressed to the effective management of technology projects issues in compliance with international standards, national regulations, client procedures and specifications, together with reference best practice and techniques.

Major activities:

- RAM(Reliability, Availability and Maintainability) analysis

- RCM(Reliability Centered Management) analysis

- RBI(Risk Based Inspection) analysis

- Spare parts analysis

- M&I plan

- CMMS and CIMS implementation

- Organization management and procedures development

Pre-commissioning & Commissioning Engineering (Preparation)

Prepare and issue the master document register for pre-commissioning & commissioning sub-system’s limits identification by marking up on engineering/vendors P&ID and one line diagrams.

Pre-commissioning engineering

Major activities

- Population of the pre-com database in PCS

- Review and update of the pre-com check and test sheets

- Preparation of the pre-commissioning planning

- Preparation of the pre-commissioning dossiers to be filled in during the Pre-com execution phase

- Prepare and issue the pre-com management procedures

- Prepare and issue the pre-com procedures

- Prepare and issue the pre-com progress report format

Dossiers

- RFC certificate and RFC punch list

- Sub-system limit marked-up drawings (ie P&IDs, SLDs, loop drawings)

- Pre-commissioning status index and check/test sheets per discipline

- Pipe work flushing, cleaning, drying, leak test testing and inerting reports

- Equipment inspection and survey reports

- RFC preliminary check reports per discipline

- First fill chemicals schedule

- Preservation schedule

- Vendor report

Commissioning Engineering

Major activities

- Validation of the subsystem breakdown and sub-systems limits

- Definition of the commissioning databases

- Population of the commissioning database in PCS

- Definition of the punch list database format

- Prepare and issue the start-up sequence

- Prepare and issue the commissioning planning

- Preparation of the commissioning manpower (including assistance by vendors and construction contractor)

- Preparation of the commissioning mobilization plan

- Preparation of the commissioning Management procedure

- Preparation of the commissioning procedures

- Preparation of the operational tests procedures

- Preparation of the performance test procedure

- Definition of the commissioning spares, temporary equipment, test equipment

- Prepare and issue the commissioning engineering progress report

Dossiers

- Ready for start-up certificate and associated punch list

- Sub-system limits marked-up drawings

- Commissioning status index and functional test records

- Relevant marked up "as commissioned " drawings (ie P&IDs, SLDs , loop drawings)

- Relevant marked up "as commissioned " vendor drawings and reports

- OT preliminary checks reports

- Operational test procedures

- Operational test certificates

- Start-up , operating and maintenance procedures when applicable

- Pipe work and equipment leak test and inerting reports

- Equipment inspection and survey reports

- Preservation schedule

- List of modifications

Operating Manuals

ISSAC E&C provides complete operating documentation and technical consultancy services, from initial concepts and planning through to development and production stages and final handovers, ensuring projects are delivered safely, on time and within budget. We have been providing documentation and technical information services to the oil & gas industries/marine projects and have supplied manuals to many clients.

- Philosophies, ship-specific procedures

- Pre-commissioning & commissioning procedures

- Field start-up procedures

- Operating manuals

- Interactive manuals

- Maintenance manuals

- O&M integration manuals

- Process system procedure manuals

- Cargo, deck, bridge and E/R system manuals

- SOLAS & fire fighting manuals

- Training manuals

Interactive manuals

In addition to the traditional paper-based, we provide interactive operating manuals and, if necessary, the IT system needed to support its deployment. Interactive operating manuals help reduce paper use and avoid having conflicting versions in circulation. Multiple users can consult the same interactive manual at the same time. They are portable and can be used online or offline, if no internet connection is available. They can also be used as an e-learning tool.

Noise/Vibration Measurement & Analysis

Noise/Vibration measurement service

ISSAC E&C measures vibration/noise levels and provide measurement report according to the scheme for all ships.

Noise and vibration means technical defectiveness originated from design stage or construction stage. It decreases efficiency of power and increases mechanical impairing.

- LQ, hull& topside measurement

- Gathering data & analysis

- Document report

Analysis & commissioning

We provide practical solutions to avoid excessive noise and vibration at design stage.

We also confirm the acceptance of noise and vibration limits based on international standards, by performing noise and vibration measurements during sea trials.

- Global vibration & Noise analysis

- Local vibration analysis- Vibration isolation design

- Analysis & consulting

- Coordination of noise and vibration

- Initial design review

- Global vibration analysis for the whole vessel

- Local vibration analysis for the structure and machinery

- Noise analysis for the whole vessel

- Noise propagation analysis for the outdoor space

- HVAC noise analysis - Test and commissioning

- Exciter and modal test for the evaluation of dynamic characteristics

- Sound insulation test including impact sound

- Silencer performance test (FAT, onboard)

- Global and local vibration measurement during the sea trial

- Noise measurement during the sea trial

- Troubleshooting for noise and vibration problems

Shaft power & ship performance measurement

Shaft power measurement

We provide shaft power measurement services in accordance with the sea trial procedure.

Principal measuring services are as follows:

- Torsional vibration measurement

- Axial vibration measurement

- Shaft power measurement

- Whirling vibration measurement

- Dynamic behavior analysis of the shaft system

Ship performance measurement

We provide ship performance measurement services in accordance with the sea trial procedure.

Principal measuring services are as follows:

- Sounding-pipe measurement

- Deadweight measurement

- Inclining experiment

- Progressive speed test

- Maneuvering test

- Wave measurement

- Rudder torque measurement

- Crash stop astern test

Structure Design & Analysis

Ships

ISSAC E&C provides a comprehensive and reliable structural design & analysis for the ship structure, complying with the relevant hull structural rules.

- G/A, building spec review

- Initial rule scantling

- Direct strength analysis

- Direct strength analysis

- Hull key plan

- Detailed hull structural drawing

- Hull production drawing

Offshore plants

We provide the best solutions that maximize the functionality and productivity of offshore structures, based on broad experience and technology.

- Hatch

- Burner boom

- Helideck

- Wind wall

- Lifting frame

- DIFFS lifting